As the LNG bunkering ecosystem evolves, with new supply chain dynamics, stricter regulations, and greater competition among suppliers - designers of LNG cargo systems must adapt their solutions. In this context, GTT has introduced the 1 barg tank design pressure solution, providing LNG bunker vessels with greater flexibility, regulatory compliance, and cost efficiency.

Why 1 barg?

The 1 barg design pressure for LNG bunker vessels has received multiple Approvals in Principle (AiPs) from leading Classification Societies, following comprehensive risk assessments. This configuration offer several advantages:

- Operational Flexibility: The ability to load LNG at higher temperatures, up to -153°C, ensures compatibility with a broader range of LNG supply sources, including regasification terminals, as illustrated in the table below.

Assumption: LNG composition is defined according to the IGF Code. The possible temperature range becomes wider when LNG contains little nitrogen, providing greater flexibility.

In addition, the amount of natural gas that can be stored in the vapor space increases by approximately 4,500 kg (for an 18,600 m³ LNG bunker vessel at 50% LNG volume) compared to 0.7 barg. This offers more operational flexibility during LNG bunkering, particularly when return gas is limited.

|

Pressure Safety Valve Pressure setting |

0.7 barg | 0.8 barg | 0.9 barg | 1 barg |

|

Max loading temperature of LNG |

-155.6 °C | -154.8 °C | -154 °C | -153.3 °C |

|

Extra mass of gas compared to 0.7 barg |

Reference | + 1,500 kg | + 3,000 kg | + 4,500 kg |

However, it is important to recall the benefits of maintaining the vapor space at the lowest possible pressure at all times in order to preserve a comfortable safety margin.

- Energy efficiency: Reduced reliance on subcoolers during standby or idling phases lowers electrical consumption and optimises energy use.

- Regulatory readiness: Extended holding times support compliance with emerging environmental standards, such as AFNOR recommendations on cold ironing.

A Decade of Development

GTT’s work on elevated pressure LNG containment systems spans over a decade, in close collaboration with Classification Societies:

- Cruise Vessel Fuel Tanks: Alternative design approved for 2,600 m³ tanks at 2.0 barg, used during bunkering and emergency scenarios. Reference Vessel: Commandant Charcot (IMO 9846249) ordered to GTT in 2018 with close to 5 years of operation in LNG.

- LNG Brick™ Tanks & Bunker Vessels: AiPs for 2,000 m³ tanks at 2 barg and 4,000 m³ tanks at 1 barg under the IGC Code.

- Ultra Large Container Vessel (ULCV): Recent AiPs for 1 barg tanks under the IGF Code, granted by BV, ABS, and DNV.

Technical Implementation

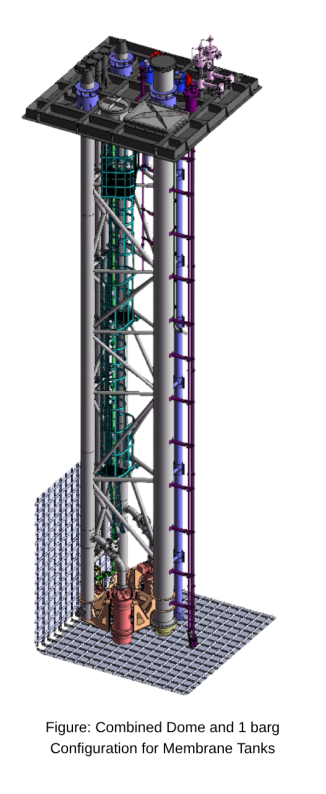

For shipyards, adopting the 1 barg configuration requires limited adjustments across few areas, despite containment system main components remaining completely unchanged:

1.Containment System Design

- Reinforcements limited to the dome cover (thickness, stiffeners, crossing pieces, welds, and bolts).

- Additional non-destructive testing (NDT).

- Pump tower optimised thanks to adapted dome dimensions.

2.Inner Hull Reinforcements

Minor structural upgrades to cofferdam bulkheads, tank tops, dome seats and double bottoms are necessary to accommodate increased pressure.

3. FGHS Equipment Adjustments

- Pressure Safety Valves (PSVs) with dual settings (1.0 barg for normal operation and 0.7 barg for alternative containment scenarios).

- Updated high-pressure alarms and expanded sensor ranges.

- Compressors and heaters adapted to wider inlet pressure ranges.

Operational Savings

Following chart shows how savings on subcooler power consumption are increased when idling duration and/or tank design pressure is increased. Idling varies from 1 to 5 days and design pressure of 0,7 barg and 1 barg are shown.

Power Consumption Comparison between 1 barg and 0.7 barg

To illustrate, 490 kW of electrical power are saved for 1-day idling, figure increased to 980 kW for 3 days, from design pressure upgrade.

Key Assumptions:

- Subcooler is TBF 700 or equivalent.

- Since operating LNG bunker vessel at high pressure is not recommended due to off-LNG specification risks, LNG temperature is to be brought down to customer LNG temperature requirement at end of idle.

The 1 barg design pressure is now a certified by many Class societies while becoming a practical upgrade for LNG bunker vessels. Besides offering huge operational flexibility and operating costs savings to Shipowners and Charterers, Shipyards are now in position to upgrade their standard offer for bunker vessels.