GTT has developed a new LNG tank concept, GTT CUBIQTM, specifically designed for merchant vessels, with a focus on LNG-fuelled container ships. Drawing on several years of operational feedback from in-service vessels, the concept combines lessons learned at sea with advances in sloshing methodology, tank engineering refinements, and a close alignment with evolving regulations.

A Major Design Evolution

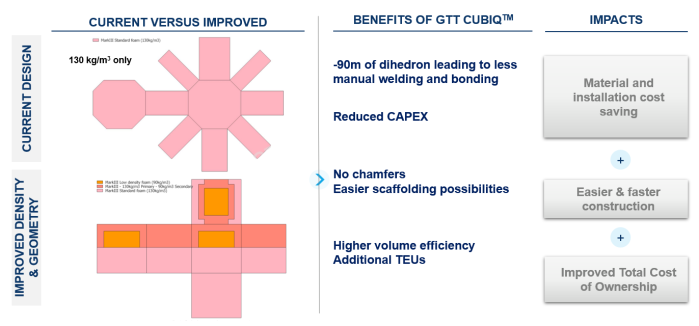

By eliminating the traditional chamfer in fuel tank geometry, GTT engineers have reduced corner areas and simplified construction, unlocking a range of operational and economic benefits for shipbuilders and ship-owners.

This geometry delivers clear benefits for ship-owners in three key areas:

- Design efficiency: The optimised geometry offers better enhanced volumetric efficiency, more usable space and lower construction cost per cubic meter.

- Ease of construction: Thanks to standardised geometry, scaffoldings are simplified, installation time is shortened, and complexity reduced, making the construction process faster and more efficient.

- Improved Business Case/Total Cost of Ownership: a lower boil-off rate (BOR) allows downsizing of the fuel gas system, reducing operating costs and freeing up additional cargo space.

Designed for Real-World Operations

The GTT CUBIQTM concept is suitable for LNG-fuelled tanks up to 25 meters wide and 14,000 m³ in capacity exceeding the requirements of long distance operations such as Europe to South-East Asia routes. It supports different insulation options, including standard foam or hybrid foams, achieving an optimised BOR. Testing campaigns confirmed the necessary reinforcement levels required, enabling a lighter containment system at 1 barg design pressure, affording compliance with cold ironing regulations.

Behind the Innovation: Three Main Drivers

1. Operational feedback

The first generation of membrane fuel tank designs focused on maximising fuel autonomy, as LNG was initially harder to bunker. Increasing onboard LNG volume reduced the risks linked to frequent bunkering and enabled the owner to bunker at the cheapest port. Today, smaller tank capcities are increasingly possible.

2. Refinement of Sloshing Methodology

Additional model tests and sloshing simulations have significantly improved GTT’s post-processing statistical analysis and refined its analytical models. These advances make it possible to design more precise reinforcement arrangements and to use lower-density materials in selected areas. The result is a lighter containment system with improved thermal performance, bringing benefits to both yards and ship-owners/charterers.

3. Regulatory Developments

The release of IACS (International Association of Classification Societies) recommendation No. 34 has introduced more realistic environmental conditions based on decades of buoy and satellite data. Therefrom, additional simplifications have been possible, confirmed by advanced simulations and model testing, aligned with sea state conditions likely to be encountered by LNG-fuelled vessels.

By redefining LNG fuel tank geometry, GTT CUBIQTM delivers a simpler, more efficient and cost-effective solution, helping shipyards and ship-owners improve construction schedule and vessel performance while reducing operating costs, as summarised below.

Figure: GTT CUBIQTM LNG Fuel Tank - Summary of Benefits